This kit from 2000 has quick build wings and fuselage. The flaps do not have a nutplate installed to install the rod end bearing. I had to make this strange tool in order to hold the nut in order to install the bearing. A nutplate would have been awesome.

Right wing flap trimmed to fit. A repetitive process.

Left wing.

Left wing sits perfectly against the fuselage bottom after trimming. No need for any bending of the inboard flap skin. Very happy.

Right wing is also fitting very well. It takes some time running the flaps up and down and adjusting each flap pushrod (hex in my case) so that both flaps are up perfectly at the same time.

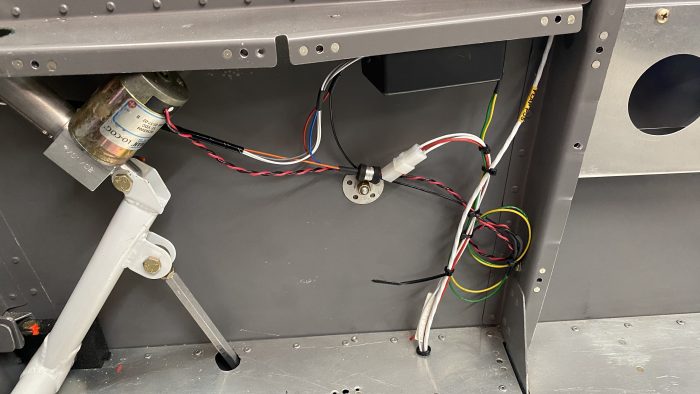

In order to get the flaps working perfectly in sync you need to install the flap motor. I opted for the FPS positioning system as I have had great experience with it on the prior 7A. On the 7A the motor is located at at the fuselage bulkhead, on the 8A it’s located on the flap weldment so if you are using the FPS you need to hog out a pretty good sized hole. It’s ok because it will be covered by a cover.

FPS system secured in place.

Flap Service Bulletin complied with.