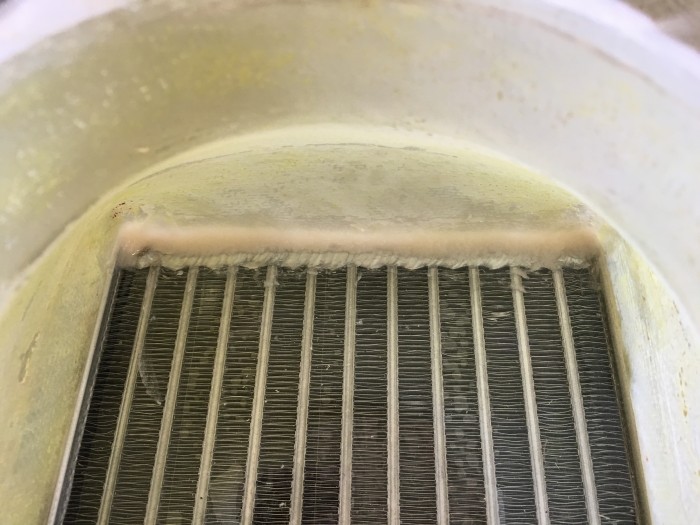

Added flox to the inside portion of the duct where it meets the sides of the oil cooler making a smooth transition to the cooler face. There’s clear tape covering the oil cooler so the flox doesn’t stick.

Added a bit more fiberglass around the opening to make it much stiffer and also added a few layers at the very top of the opening, about 3/16″, which will serve as a lip making it less likely the 4″ sceet tubing will come off when clamped. I’ll finish sanding the inside and get a few coats of epoxy on it to make it glass smooth.

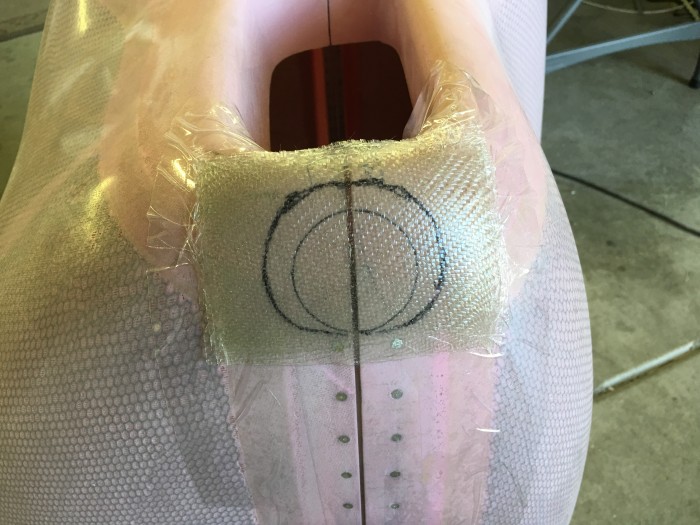

Taped over the cowling halves where the cover will go. The round circle is where the cover will go. I’m doing the same thing as I did on the last plane. See that process here.

I laid 6 layers of 8 oz cloth, enough to cover the larger circle. This first layer of glass will form the backer and will be floxed into place on the inside of the cowl, providing support to the cover plate which I will make next over the same area. This backer will get two nutplates to hold the cover plate. Make sure you trace the outline of the circles onto the dry fiberglass before you remove from cowl so you know where to cut.